DTR Facilities Compliance and Inspection Section (FCIS) Functional Statement

A robust facility compliance program is essential to ensure the Aseptic Production Facilities (APF) at the NIH meet the design intent and continuously operate in a state of control. Compliance can be defined as a state of being in accordance with established guidelines or specifications or, as efforts to ensure that organizations are abiding by both industry and government regulations.

The role of the ORF Division of Technical Resources (DTR) Facilities Compliance and Inspection Section (FCIS) shall include providing oversight of ongoing design, construction, commissioning, maintenance and operations oversight, audit/inspection, qualification, validation and certification activities of APF NIH facilities that produce therapeutic and diagnostic products for human use, inclusive of those required to follow cGMP regulations, and aseptic processing, for those manufacturing biological products, for the production of Phase-I and II clinical trial products, pharmacy compounding of sterile products excluding those facilities that fall under the Joint Commission (JC) and (Association for Assessment and Accreditation of Laboratory Animal Care) AAALAC International. The role of the ORF Division of Technical Resources (DTR) Facilities Compliance and Inspection Section (FCIS) shall include providing oversight of ongoing design, construction, commissioning, maintenance and operations oversight, audit/inspection, qualification, validation and certification activities of APF NIH facilities that produce therapeutic and diagnostic products for human use, inclusive of those required to follow cGMP regulations, and aseptic processing, for those manufacturing biological products, for the production of Phase-I and II clinical trial products, pharmacy compounding of sterile products excluding those facilities that fall under the Joint Commission (JC) and (Association for Assessment and Accreditation of Laboratory Animal Care) AAALAC International.

The FCIS section shall be responsible for: - Establishing culture of compliance that prioritizes compliance goals.

- Developing a QA/QC program that ensures that requirements and commitments are being met.

- Developing written guidance instruments such as Design Requirements Manual (DRM) Chapter 13 guidelines, checklists and standard operating procedures to ensure that compliance and verification goals are met at a predetermined frequency.

- Ensure that designs meet the specific regulatory, DRM, code and maintenance and operations requirements.

- Ensuring that the requirements for adequate documentation; all design contract documents, Basis of Design (BOD), Project Execution Plan (PEP), User Requirements Specification (URS), contractor qualifications, commissioning/qualification plan, tests protocols, facility performance, warrantees, SOP's, O&M manuals etc,. have been met prior and during the facility operation.

- Review and approval of PEP, BOD, URS, all design contract documents, critical submittals, TAB reports, commissioning and qualification plans and protocols

- Observe construction in progress to ensure compliance with the approved plans, specifications, and all applicable codes and standards before the facility opens. Provide inspection reports for acceptance of completed work, documenting field conditions, observations and findings.

- Approving change control procedure/documents for issuing compliance if there are changes to the design documents during any phase of design or construction that changes the critical features specified for the design.

- Observe and review continuous systems/controls commissioning, re-commissioning, qualification and certifications and material test results during construction and seasonal operations.

- Developing of specific inspection and acceptance criteria necessary for FCIS to issue Certificate of Use.

- Providing oversight of DFOM Computerized Maintenance Management System (CMMS) including identifying critical spare parts and inventory. Establishing metrics and benchmarks including Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), etc.,)

- Supporting development, review and approval of facility SOPs in conjunction with Division of Facilities, Operations and Maintenance (DFOM)

- Supporting development, review and approval of Root Cause Analysis (RCA) /troubleshooting and preparation of corrective actions and preventative action (CAPA) and System discrepancy (SD) reports and work plans.

- Establishing a report and documentation system for reporting of periodic Facility Monitoring reports for monitoring of critical quality parameters and monitoring activities of FCIS system.

- Developing and maintain as built P&ID diagrams, schematics, control logic diagrams, control sequences and programming.

- Developing facilities audit program and conducting audits

- Developing training plan for DRM Chapter 13 training.

- Identification and oversight for training and staff certifications to operate and maintain facility critical systems.

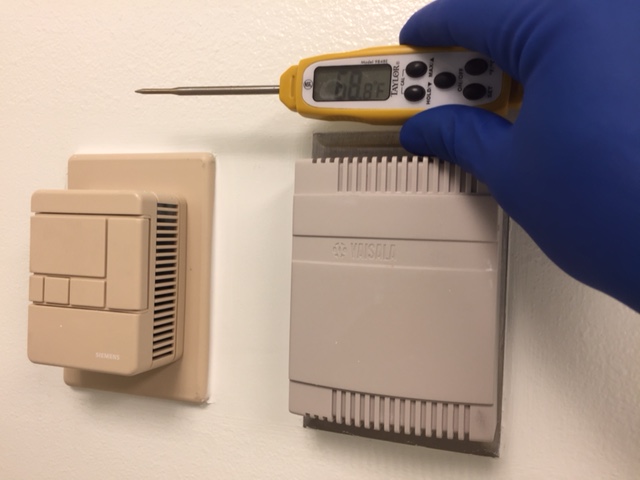

- Providing oversight for calibration and maintenance schedules.

- Identifying potential problems and advising ORF management of recommended corrective actions.

- Ensuring that corrective actions are completed within specified timeframe and to specified criteria.

- Identifying operational and maintenance (O&M) improvements that will enhance the facility's ability to meet and/or exceed existing requirements.

- Maintaining ALL critical records and support compliance with the NIH wide documentation system.

- Disseminating lessons learned.

- Establishing a feedback and program improvement system

- Establish signature authorities.

|